E-DRIVE SYSTEMS

We make customized batteries

What we offer

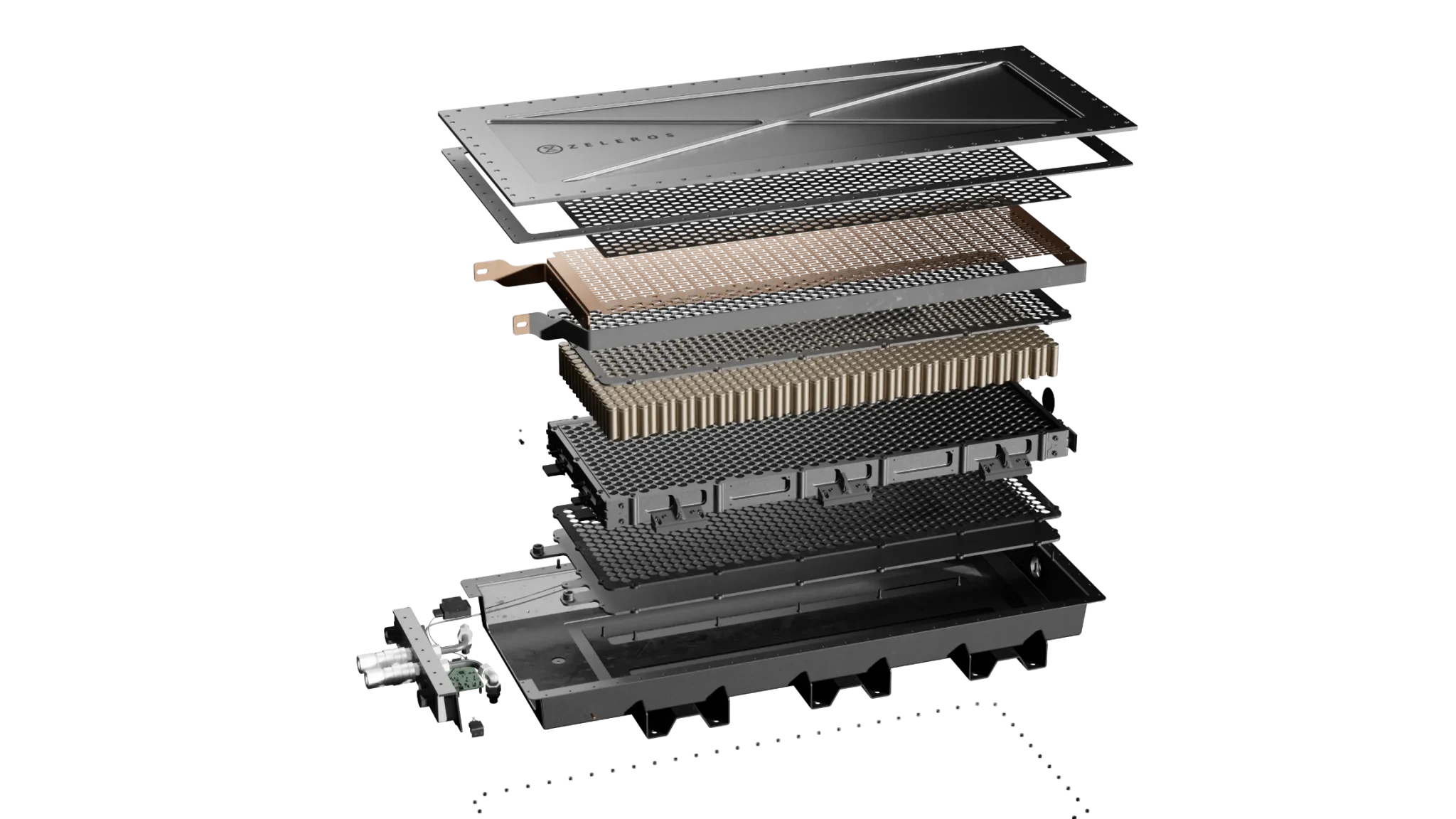

Custom Electric Batteries

Zeleros offers customized battery solutions, covering from conceptualization to production and certification. We engage with OEMs vehicle development programs taking the responsibility as Tier 1 of the battery system.

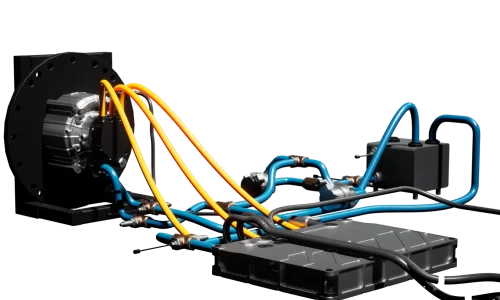

Tailored e-Drivetrains

We take competences in the scouting and selection of off-the-shelf components building the powertrain, as well as the design at electric, electronic, and mechanical level.

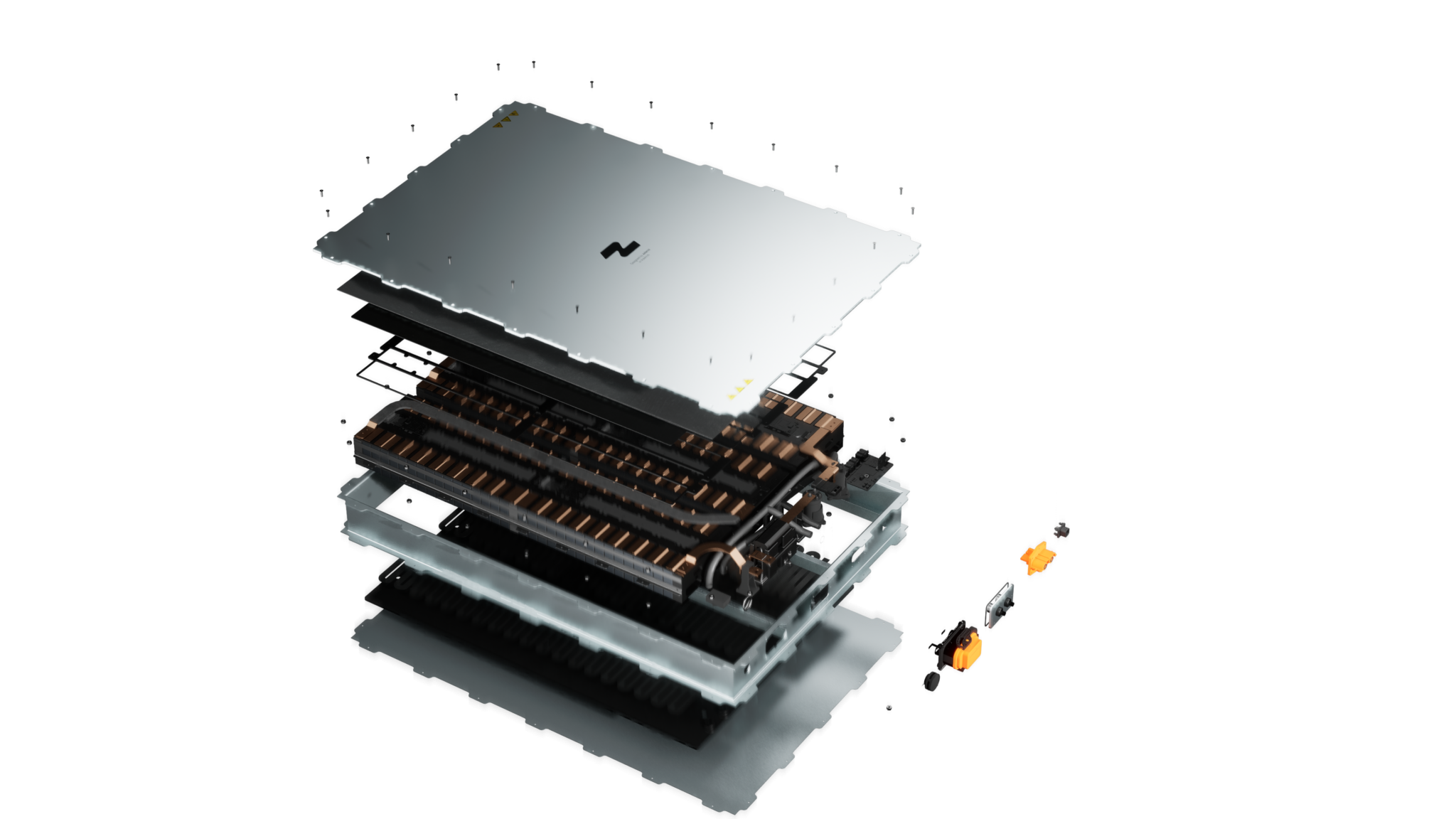

Custom Electric Batteries

120 kWh, 800V

Máximum values at battery pack levels

Scalable

All our batteries are designed to be stackable

500MWh

Our annual access to manufacturing capabilities

Certification & Tests

Thanks to our strong alliances in the industry

Tailored e-Drivetrain

Design & Engineering

Powertrain architecture design customized to your needs

Procurement

Tailored component selection & purchase

Integration

At all levels: mechanical, electrical, and electronic

Installation

Installation of the full system in the chassis taking into account the vehicle dynamics

Our products

Designed with the highest standards

What do you need?

Yes, we make custom batteries, but we also offer a portfolio of available products. Our market analysts have discovered two types of batteries that are capable of fulfilling many of our customer needs.

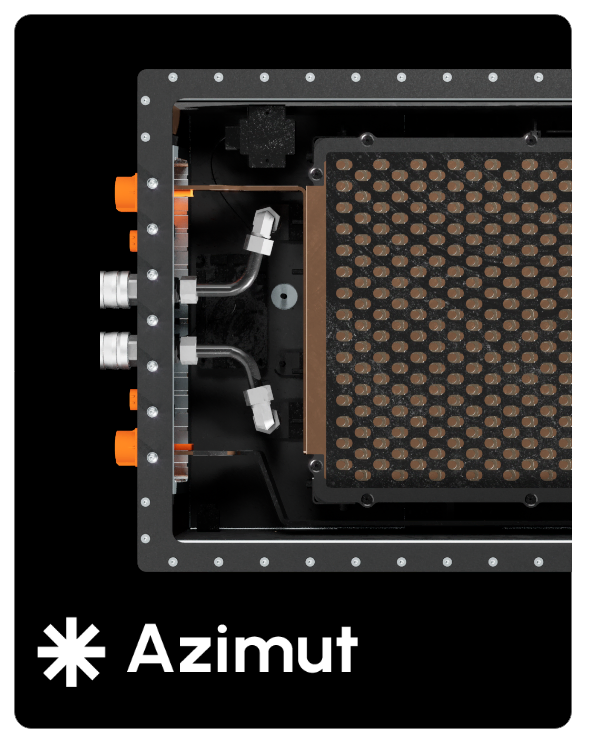

If you need POWER

choose Azimut

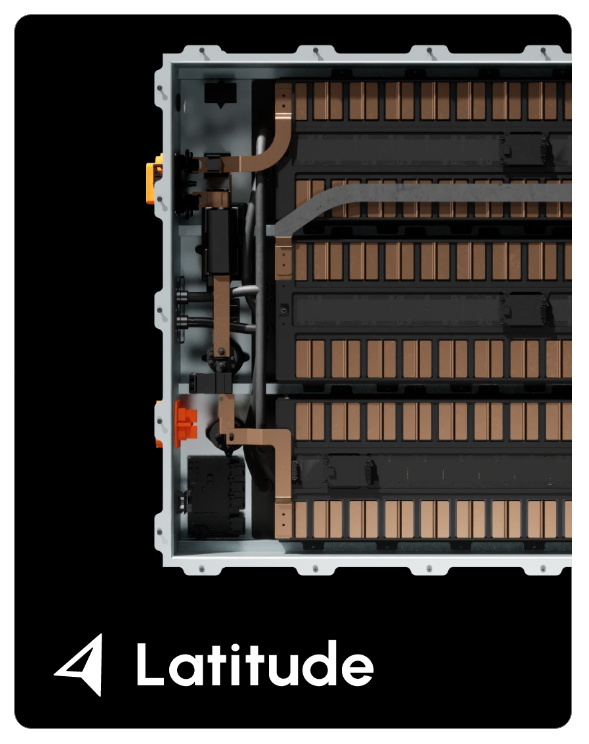

If you need BALANCE

choose Latitude

Not sure? We help you choose

Our services

Cell Selection

We help you decide & validate which chemistry, format, and dimension fits better to your target application

What We Do

Cell Selection

Select the most appropriate cell in terms of chemistry, format, and dimensions to cover the customer specifications

Cell Validation

Independent cell validation process to verify the quality and performance announced by the cell supplier

01

Pack Design

We design, manufacture and test a module ad-hoc for your needs

What We Do

Electrical Architecture

Design of the electrical architecture at module level, including components and critical processes such as welding methods

Mechanical Architecture

Customized mechanical design of the module based on computational simulations to analyze the mechanical stability vs. the expected vehicle dynamics

02

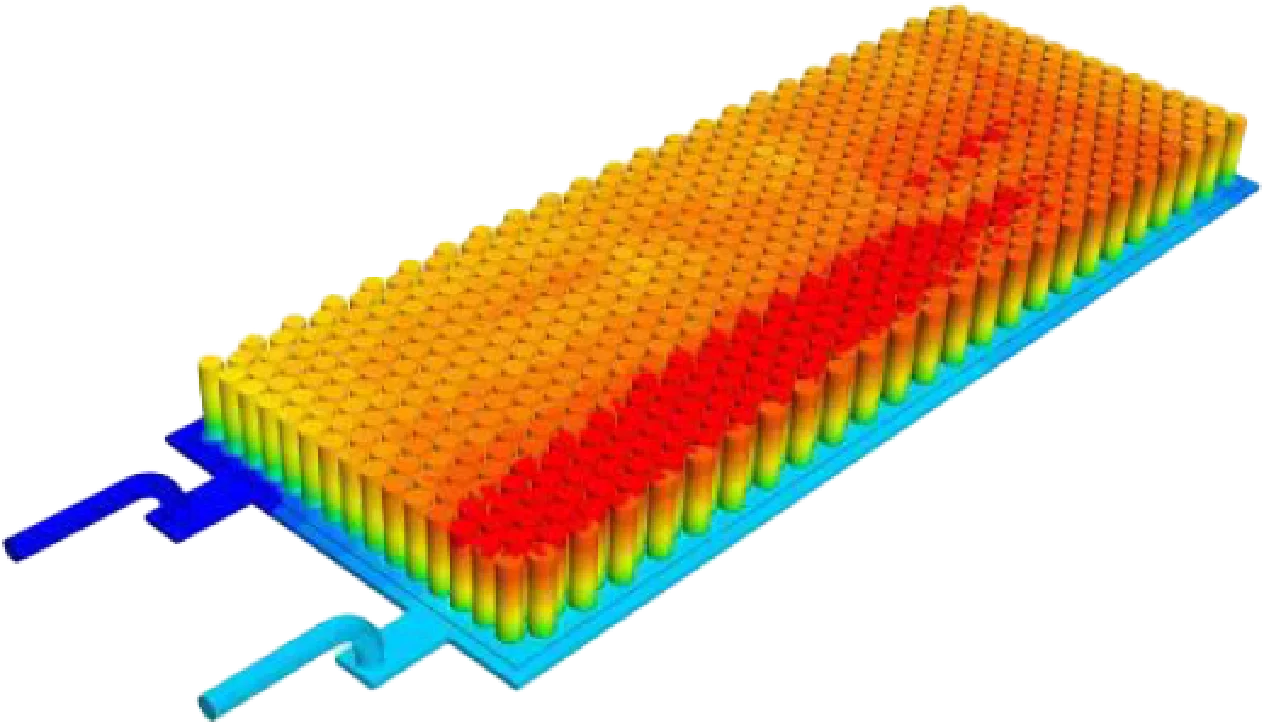

Thermal Modelling

Tailored thermal strategies to maximize performance and safety

What We Do

Thermal Modelling

Thermal analysis & simulation of the battery operation using FEM & CFD

Cooling Systems

Custom development of the cooling system based on the modelling results to ensure proper operation

Management System

Implementation of strategies to avoid thermal runaway propagation (venting caps, encapsulants, fire protection…)

03

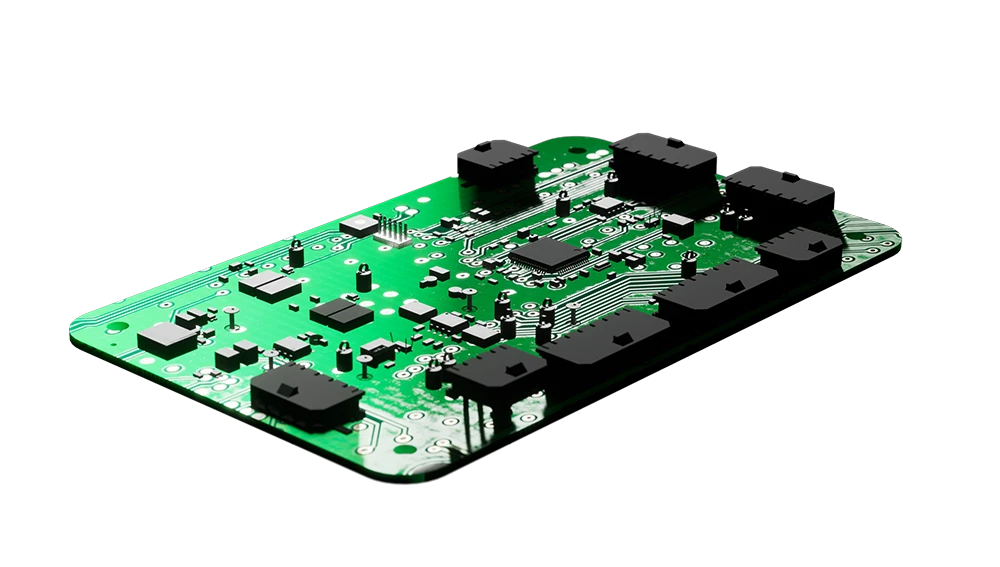

Battery Management System

What We Do

High-class customized battery software

In-house development of digital-twins of the batteries’ behavior based on the cell testing results (Model-Based Design Engineering), which allows us to obtain customized BMS algorithms of high accuracy (average of >98% match in existing references)

04

Prototype & Certificate

Customized integration & industrialization to the specific constrains and needs of your vehicle

What We Do

Battery Distribution Unit

Development of the BDU, selecting the most appropriate components to ensure safe operation through instant shutdown mechanisms

Safety/Certification Analysis

Analysis of safety requirements based on standard regulations / legislations

05

Series Production

Cutting-edge facilities at our disposal to prototype, manufacture, test, and industrialize customized battery designs. The plant serves not only Zeleros but other battery developers aiming to extend their manufacturing capacity